China’s economy has shifted from a high-speed growth stage to a high-quality development stage. Promoting high-quality development is the fundamental requirement for China to determine development ideas, formulate economic policies, and achieve macro-control. The implementation of supply-side structural reforms in all walks of life must be based on this guiding ideology. The wall material industry must unswervingly implement this requirement in order to truly achieve sustainable development.

High-strength, low-density aerated concrete should be developed

At present, Jiangsu Province has taken the production lines of aerated concrete blocks of 150,000 cubic meters and 100,000 cubic meters respectively as restricted and eliminated products, and aerated concrete plates as encouraged products, which is quite correct. Recently, Shanghai has also listed 180,000 cubic meters of aerated concrete production enterprises as a restricted list and included it in the negative list of industrial restructuring. It will no longer enjoy preferential policies such as tax reduction and exemption. Therefore, some suggestions on the technical innovation of aerated concrete slabs:

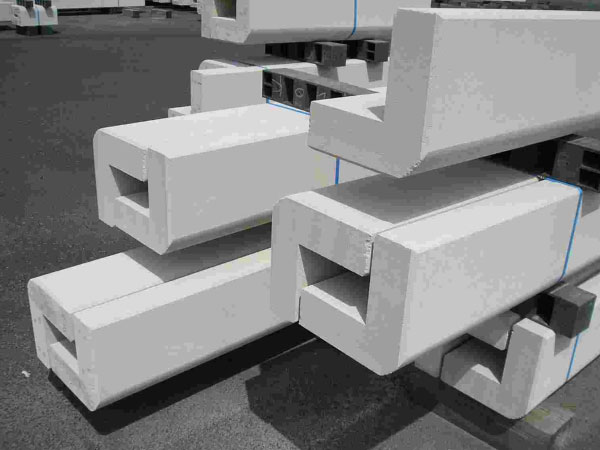

First, the development of aerated concrete panels focuses on improving the quality and function of aerated concrete itself. Aerated concrete sheet is mainly used for exterior wall insulation. From the point of view of functional requirements, aerated concrete products with low density, high strength, high heat insulation performance, and low dry shrinkage must be used. This requirement is essentially a deep-seated problem of aerated concrete quality. I have inspected related aerated concrete companies in Japan. Almost all of the aerated concrete exterior wall panels of these companies use grade 05 aerated concrete, and their standard strengths are above 4MPa (the actual ex-factory strengths are around 4.35MPa, and some have reached 4.5MPa), the performance requirements of aerated concrete for the production of slabs are higher than that of aerated concrete blocks. This requirement is not only to meet the building construction function of slabs, but also because aerated concrete is equipped with steel bars, this requirement is also to enhance aeration. Concrete and steel grip and prevent long-term corrosion of steel. Grade 06 or grade 07 aerated concrete has been used in floors or roofing panels, but it is not very common.

The aerated concrete blocks used for exterior walls in our country have a strength of 2.5 MPa or 3.5 MPa for grade 05 blocks. In order to prevent cracking, it is required that the blocks have a strength of 5 MPa. Therefore, they have to produce grade 06 or 07 aerated concrete. Most bulk density They are all in the range of 680 kg / m3 to 730 kg / m3, and some even reach the 08 level. This is inconsistent with the development direction of aerated concrete. There are three problems in the development of aerated concrete:

First, due to the multi-use of raw materials (especially high-quality quartz sand and high selling price of lime), production costs have greatly increased. In the long run, it is difficult to maintain.

The second is the production of 06 or 07 grade products, whose insulation performance is significantly reduced. Without increasing the wall thickness, it is actually difficult to meet the local building energy-saving design standards.

Third, the thickness of the wall must be increased in order to achieve energy conservation standards, resulting in increased construction costs. Therefore, only the production of aerated concrete with a density of 05 or below and a strength above 4 MPa can truly exert its excellent thermal insulation performance, meet local energy-saving standards, save raw materials, and reduce production and construction costs.

At present, most of China’s aerated concrete slabs are grade 05, 3.5 MPa concrete, which may not meet the requirements of frost resistance in cold and severe regions, and are prone to cracking and hollowing in hot summer and cold winter regions or hot summer and winter warm regions. , Peeling and other disadvantages, from the perspective of long-term use stability, it may be necessary to further increase its strength and reduce its dry shrinkage value.

Therefore, I suggest that the technical innovation focus of aerated concrete companies is to develop high-strength, low-density aerated concrete. For the production of aerated concrete external wall insulation boards, the strength of the bulk density of grade 05 must be above 4MPa, and its shrinkage value also needs to be Lowering, while strengthening the rust prevention treatment of steel bars. The high-quality development of aerated concrete is not just a matter of requiring a 4.8-meter cutting machine. Of course, according to the current situation of China’s aerated concrete plants, in order to develop low-density, high-strength aerated concrete, it is necessary to carry out a comprehensive system transformation from improving the quality of raw materials to the updating of process equipment technology.

Second, strictly control the quality of raw materials and strengthen raw material processing. Aerated concrete is a lightweight porous material with silicon dioxide and calcium oxide as the main raw materials, mixed with aeration agents, and hydrothermally synthesized at high temperature and pressure, so it contains silica and calcium oxide as the main ingredients Quality status has a great impact on product quality and performance. The silica content of foreign raw materials is about 95% to 96%, and the effective calcium oxide content in quicklime is as high as 93% to 95%. In China, the composition of fly ash in fly ash aerated concrete is not controlled. The silica content is generally 40% to 48%. The sand silica content in sand aerated concrete is mostly between 80% to 90%. Without cleaning, the mud content is high; the effective calcium oxide content in quicklime is only 55% to 60%, and the highest does not exceed 65%. Compared with foreign countries, the quality of aerated concrete raw materials in China is obviously not high, and the quality is unstable, which is an important reason for the inherent shortage of aerated concrete quality performance. Based on the results of a systematic test on the composition of aerated concrete raw materials, we recommend that existing aerated concrete plants make up their minds to improve the quality of raw materials and use as much as possible finely ground quicklime and quartz sand with high effective content of calcium oxide and silica. The aerated concrete sheet has higher quality performance requirements than the block. It is best to use fine lime with a calcium oxide content of 80% to 90%. The sand must be washed, ground, and mixed with a part of ground silica with high silica content. sand.

Third, focus on strengthening the technological transformation of equipment and increasing the curing temperature and pressure of autoclaves. The autoclaved temperature and pressure of aerated concrete in China are mostly 1.2 MPa to 1.3 MPa, and the corresponding temperature range is 190 ° C to 195 ° C. The hydration products generated under this temperature and pressure have not been fully crystallized. For many years, there is an inaccurate understanding in the aerated concrete industry. It is believed that as long as CSH hydration products are generated, regardless of the type, quantity and form of Tobmorite, it is considered to be aerated concrete with good performance. Low autoclave, in fact, at different temperatures and pressures, there are many hydrated products of tobomolite, which have colloidal, needle-like crystals, plate-like crystals, and plate-like crystals. These waters The types and quantities of chemical products in the mixture are different, and their effects on the performance of aerated concrete vary widely. In Germany and abroad, the autoclaved temperature and pressure of aerated concrete must not be lower than 1.5MPa and 203 ℃. According to the experimental research on physical and chemical properties, only under such a high pressure (temperature), the silica and calcium oxide in the material can fully perform the hydration reaction to produce C4S5H5 crystals (hard silicon calcium with good crystallinity and plate shape). Stone), and the quantity is sufficient, which constitutes a product with low shrinkage value and high strength. Therefore, in order to produce external wall insulation boards, existing aerated concrete enterprises in China must also upgrade the autoclave equipment with lower pressure at the same time. This is an important measure for aerated concrete enterprises to achieve real upgrading.

Two points need to be paid attention to: First, for aerated concrete-type lightweight materials, when evaluating its strength index, it must correspond to its associated density, instead of just indicating the strength regardless of the density. Second, due to the large difference in silica content between fly ash and quartz sand, coupled with the complex composition of quicklime in China, the effective content of calcium oxide is relatively low. According to experimental research, fly ash aerated concrete and sand aerated concrete The hydration products are not exactly the same. Under the same density, the product’s water absorption and drying shrinkage value are significantly different. Therefore, when developing fly ash aerated concrete slabs, we must pay more attention to the raw material composition and technical strictness. check.

Actively develop prefabricated building boards

In the past, we have repeatedly emphasized that wall material innovation is not a simple replacement of solid clay bricks. Its ultimate goal is to improve building functions, including the development of energy-efficient buildings, the promotion of technological progress in the construction industry, and the modernization of the construction industry. Prefabricated building is an important part of the industrialization of construction. It includes the industrialization of the production of building components and the assembly of construction and installation. Therefore, the development of prefabricated buildings has the advantages mainly reflected in two aspects: first, the production of building components including building boards, Adopting advanced industrialized production technology to ensure product quality performance and use functions, the company achieves the purpose of improving quality and efficiency, and saving raw materials. The second is to use advanced mechanized construction technology to assemble on site to greatly improve construction efficiency and reduce project cost. Both of these are indispensable, no matter from the development process of residential industrialization or construction industrialization in Europe, America or Japan.

From the current development of prefabricated buildings in China, the main prefabricated building components are slabs. Its installation and construction adopts mechanized assembly to develop rapidly, and the degree of construction mechanization has greatly improved, thereby improving construction efficiency, which has promoted the development of prefabricated buildings effect. However, in terms of slab production technology, most of the domestic are still produced in the factory by the traditional manual pouring concrete method. Some are coupled with automatic linkage technology in the process to reduce manual handling. Most of their products are solid reinforced concrete slabs. Sandwich insulation material or foam concrete between two layers of solid reinforced concrete slabs inside and outside. From the current application situation, these types of plate products reflect two problems. One is that the plates are too bulky and it is inconvenient to lift and install. Some construction sites have difficulty in construction due to the lack of large lifting equipment. The cost is greatly increased, and some are even at least 30% higher than that of masonry or cast-in-situ construction. The current problems in these two aspects restrict the rapid development of prefabricated buildings. In view of this situation, actively developing advanced production technology and new product structure types of prefabricated building panels to reduce the weight of the board, improve production efficiency, and save production costs may be an important part of the development of prefabricated buildings in China.

It is incumbent on wall material companies to develop advanced production technology and new structural types of fabricated building boards. In 1996, the “Notice on the Cooperation of Construction and Construction Materials Departments to Promote the Modernization of Residential Buildings” jointly issued by the former Ministry of Construction and the State Building Materials Bureau emphasized that with the breakthrough of wall materials to promote the modernization of the residential industry, it can be considered that the research and development of building board production Technology is a strength of the wall material industry. Over the years, many wall materials companies have laid a good technical foundation in the development of building wall panels, such as ceramsite concrete hollow slabs, aerated concrete slabs, GRC lightweight hollow slabs, industrial ash concrete Quality partition board, gypsum board, autoclaved fiber cement board, etc. Therefore, in terms of panel technology innovation, in addition to further improving the existing wall panel quality and process technology level, wall material companies can learn from the prestressed tensioning process technology currently popular in Europe, America and Japan to develop and develop prestressed concrete hollow panels. Including insulated composite hollow plates. Through extensive investigations abroad, this process technology not only greatly reduces the weight of the slab, but also improves the quality and performance of the slab product, and improves the strength and crack resistance of the slab concrete. Compared with ordinary reinforced concrete, it can save at least 20% of the concrete. % ~ 25%, saving steel by 25% ~ 40%, the hole ratio can be up to 45.8%, and the weight can be reduced by 30% ~ 40%. It can be used for interior and exterior wall panels, floor slabs, roof panels, and large-span floor slabs. Used in public buildings (schools, conference halls, halls) and industrial buildings. Because of its connection method, beard tendons are used for banding or welding, and the micro-expanding fast hard cement mortar is poured, which greatly enhances the integrity and stability of the house structure.

It needs to be emphasized here that some people may say that China’s production and application of prestressed concrete hollow slabs in the 1970s were generally unsuccessful, so they mistakenly believe that China’s development of prestressed concrete hollow slabs is not suitable for prefabricated buildings. This is a kind of misunderstanding. In foreign countries, regardless of the European and American countries or Japan, the prefabricated buildings of steel or reinforced concrete structures all use prestressed concrete plates as floor or wall panels, and they are even used as non-beam or column-type building structures. As for the unsuccessful application of prestressed concrete hollow slabs in the 1970s, it was because the production process technology was not perfect at that time. The prestressed steel bars were stretched on the movable formwork and the concrete was vibrated on the shaking table. The vibration caused the two forms of the formwork. The prestressed steel reinforcement pin at the end is loose, the prestress fails, and the quality of the plate fails to meet the functional requirements. In addition, the construction technology uses non-joint overlap, and the installation technology is backward. Therefore, this does not mean that the prestressed concrete hollow plate is not suitable. Prefabricated buildings, foreign prefabricated buildings use a large number of advanced prestressed concrete hollow slabs to fully prove this.

The development of prestressed reinforced concrete hollow building boards is an advanced technology for the production of building components. At present, there are two ways to develop this technology in China. One is that conditional enterprises can develop independently and build on the existing prestressed tensioning technology in China. , To carry out the experimental development of prestressed tensioned hollow slabs; the second is to introduce key foreign equipment technology and related auxiliary equipment to support domestically, based on the introduction of high-level localization. Both of these approaches are possible. The key is that companies must carefully analyze and research the actual needs of the local construction market and the development of prefabricated buildings, determine development goals and technical routes, and actively carry out experimental research to develop new types suitable for China’s national conditions. Prefabricated building board and its advanced production technology.

With the changes in China’s economic construction situation, although wall material innovation has encountered various challenges and difficulties, it is a major measure for China to implement a sustainable development strategy and an important part of the country’s promotion of a circular economy. There are many problems that need to be solved urgently, and there is a lot of content to carry out technological innovation. Therefore, the high-quality development of wall materials is the mission of wall materials companies in the new era, and it is also the only way for the sustainable development of enterprises. Both enterprises and industry managers must be brave. Fulfill responsibility, dare to take responsibility, strengthen confidence, not be intimidated by temporary difficulties, not be disturbed by various noises, and actively participate in high-quality development actions with correct values and strong sense of responsibility and urgency. The original intention, perseverance, with perseverance and perseverance, to advance the cause of wall material innovation.