Autoclaved aerated concrete, also known as autoclaved cellular concrete (ACC) and autoclaved lightweight concrete (ALC), is a precast building material which is thermally insulating, easily shaped, highly workable, fire resistant, acoustically insulating, water and mold resistant, and can be used in both and non-structural applications. It is an ultra-light concrete masonry product offering superior workability, durability, and flexibility. AAC consists of basic materials such as sand, cement, fly ash, lime, aluminum powder paste, gypsum, and water. The chemical reaction between aluminum paste and alkaline elements in the cement provides AAC with lightness, distinct porous structure, and insulation properties which are completely different from other lightweight concrete materials.

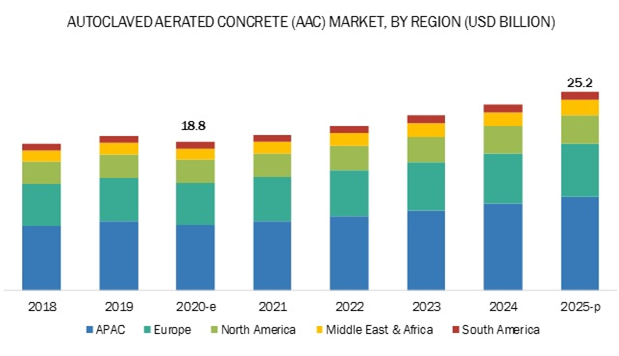

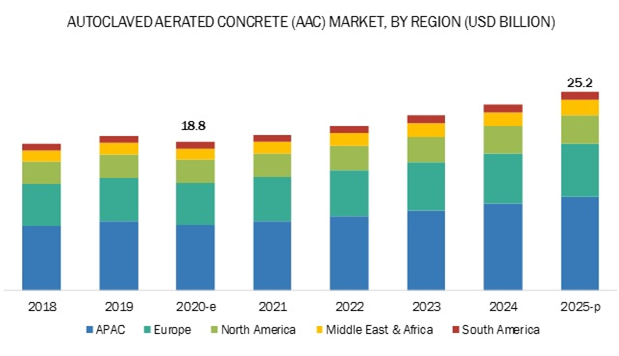

The APAC AAC industry is segmented as China, Japan, India, South Korea, Australia, and Rest of APAC. APAC is projected to continue its dominance over the market until 2025. Increasing population and urbanization in the region are the primary reasons for the growth of the AAC market in the region. China’s emergence as a global manufacturing hub has increased the demand for blocks. Cheap labor and easy availability of raw materials boost the production of these materials in the region.