Beibo’s new product silicon nest production line ignites the “Luoyang Plan” to accelerate the development of prefabricated building industry

On the morning of November 11th, the new glass nest production line for Beibo, a new product in Ruyang County, was ignited. This project achieved comprehensive innovation in the dimensions of basic materials, production processes, and product applications, and will provide a complete quality development for the assembled building industry. “Luoyang Plan.”

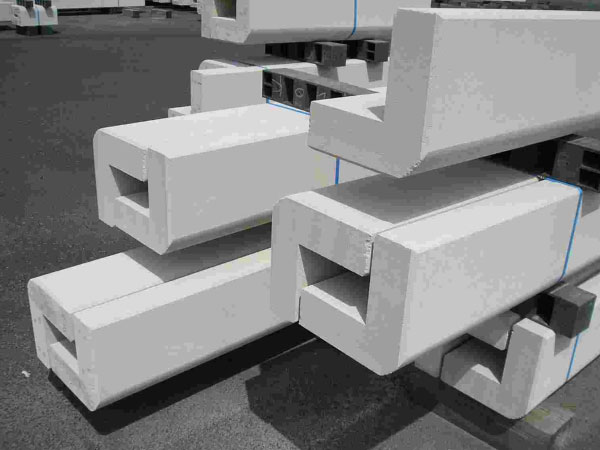

Jiang Wei, general manager of Beibo Silicon Nest, introduced that Silicon Nest is a new material produced by using special thermoforming technology based on the strong research and development capabilities of Beibo, using tailings waste as raw materials. Hive, hence the name “silicon nest”. Using the silicon nest unit curtain wall composed of this material, the actual weight is only about 1/4 of the prefabricated concrete member, which can be flexibly applied to the unit curtain wall system and prefabricated building system. This type of curtain wall has both the characteristics of exterior decoration and solid wall, and makes the building’s exterior wall more colorful, more energy-saving and thermal insulation, and more economical and applicable.

“As a unique new technology system of Beibo Silicon Nest, the Silicon Nest project has comprehensively innovated in three dimensions of basic materials, production processes and product applications, solving a variety of problems in the application of solid walls and filling the industry gap.” Gao Xueming, chairman of the company and Beibo Silicon Nest, said.

In order to solve the problems of high energy consumption and pollutant emission of silicon nest production, this project is the first in the world to apply the electric heating three-layer roller kiln technology. Compared with traditional gas heating, the finished product produced by this technology has more uniform foaming, The overall performance is better, and the whole process is pollution-free. Through subsequent interconnections with various devices of the intelligent automated production line, the production line started this time can also form cyclic manufacturing production, which can meet the process requirements for continuous production of silicon nest boards, achieve continuous and efficient cyclic manufacturing production, and greatly reduce labor costs.

Solving the problem of tailings recycling and achieving pollution-free life cycle is also a major feature of the project. The production materials of silicon nest are solid waste mainly composed of aeolian sand, silt, tailings, coal gangue, etc., which solves the related recycling problems. After the application is dismantled, all such products can be recovered, crushed and reused, and because the recycled materials are melted clinker, the energy consumption of the production process can be further reduced.

At present, China is vigorously promoting the industrialization of construction, and prefabricated construction is the main mode of construction industrialization. Beibo’s silicon nest panels and silicon nest unit curtain walls are in line with the state’s encouragement policies, and in line with the direction of environmental protection and resource recycling. It is an ideal new wall material for the city to realize prefabricated houses and prefabricated curtain walls. According to the plan, a total investment of 600 million yuan in the North Glass Silicon Nest Assembly New Building Material Project will build two silicon nest material production lines. After the project is put into operation, it is expected to achieve an annual sales income of 1 billion yuan, and an additional 300 million yuan in profits and taxes.

Industry policy

Announcement of the Ministry of Housing and Urban-Rural Development on the release of the industry standard “Technical Standards for the Treatment of Construction Waste”

The “Technical Standard for the Treatment of Construction Waste” is now approved as the industry standard, numbered CJJ / T134-2019, and will be implemented as of November 1, 2019. The original industry standard “Technical Specifications for Construction Waste Disposal” (CJJ134-2009) was repealed at the same time.

This standard is published on the portal website of the Ministry of Housing and Urban-Rural Development (www.mohurd.gov.cn) and published by the China Construction Industry Press organized by the Standard Quota Research Institute of the Ministry of Housing and Urban-Rural Development.