Economy and Application of Autoclaved Aerated Concrete Panel

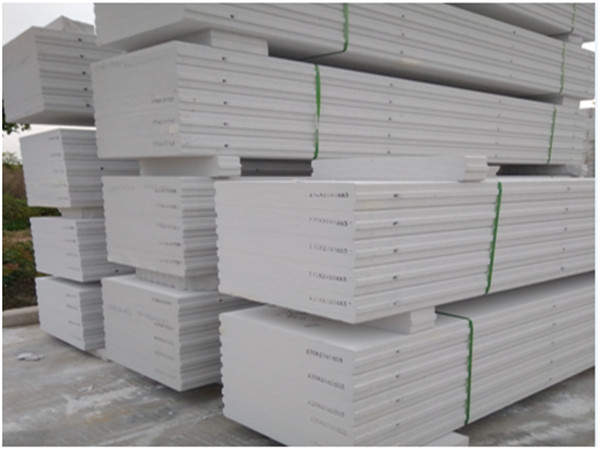

Autoclaved aerated concrete panel is made of cement, quartz sand and lime as the main raw materials, aluminum powder as the foaming agent, and adopts the patented technology formula, which is a high-performance uniform porous silicate board made by high-pressure steam curing. The steel plate is equipped with reinforced steel mesh treated with patented anti-rust and anti-corrosion technology, which can meet different structural design requirements. It has superior lightness, thermal insulation, fire resistance, sound insulation, bearing capacity, shock resistance, impermeability and environmental protection.

Comparison of performance and cost of autoclaved lightweight aerated concrete and other wall materials

1. Direct economic benefits

The price of autoclaved aerated concrete panels is between autoclaved lightweight aerated concrete blocks and other lightweight wall materials, but due to the characteristics of the material itself, it is determined that the construction is fast, special repair powder, jointing agent can repair the jointing energy Effectively reduce the occurrence of cracks on the wall, without plastering the wall surface, using autoclaved aerated concrete slabs to increase the indoor area of about 4500m2 compared with traditional aerated concrete block walls.

In summary, the direct cost per square meter can save about 30 yuan. The use of aerated concrete wallboard covers an area of nearly 140,000 m2, which can save about 4.2 million yuan in cost.

2. Indirect economic benefits

Reduce the intermediate links of construction and speed up the project progress; reduce the generation of cracks on the wall; no plastering on the wall surface; environmental protection and energy saving in the production and construction links improve product quality and achieve energy saving and emission reduction effects.

Autoclaved aerated concrete panel has the following innovations

1) Reinforced mesh treated by autoclaved aerated concrete panel anti-rust and anti-corrosion technology increases the service life of the wall panel;

2) The application of autoclaved aerated concrete panels reduces other construction procedures, and the construction method is more convenient;

3) No harmful substances are used in the whole process of the production process. The finished products do not contain harmful substances, and water and materials are recycled. The construction and installation adopts dry method operation, which does not affect or pollute the environment. After testing, the internal exposure index of the material is only 0.2 (standard requirement ≤1.0), and the external exposure index is 0.1 (standard requirement ≤1.0), which is non-radioactive. Green materials that do not contain harmful substances;

4) The indexes of thermal insulation, fire resistance, sound insulation, bearing capacity, seismic resistance, impermeability, etc. all meet or exceed the requirements of the standard;

5) This material can also be combined with thermal insulation materials, and can be used as an external wall to make various shapes, decoration, heat preservation, and maintenance integrate multiple functions in one;

6) Reducing the weight of the structure, improving the stability of the structure, and saving costs, saving about 4.2 million yuan in investment than aerated concrete blocks;

7) Due to the construction method and the size of the wall itself, the use of autoclaved aerated concrete panels increases the indoor use area by about 4500m2 compared with other wall materials.

To sum up

1) Effectively and effectively solve the problem of filling the wall cracks, increasing the indoor use area of the building;

2) By contrast, the technological content of the project construction has been improved, the construction products are more energy-saving and environmentally friendly, and the product quality of the real estate has been improved;

3) Lightweight, thermal insulation, fire resistance, sound insulation, bearing capacity, shock resistance, impermeability, and environmental protection are all superior performances;

4) As an environmentally friendly product, autoclaved aerated concrete slab conforms to the current requirements of “taking science and technology as the guide, energy saving and emission reduction as the priority, and building a low-energy demonstration project”, and has the role of radiation.

The exterior wall of the building adopts aerated concrete blocks, considering the material, construction process, construction schedule, construction quality cost and other factors. After the organization of the expert demonstration meeting, the use of autoclaved aerated concrete panel is more reasonable.