What are the advantages of autoclaved aerated concrete panels?

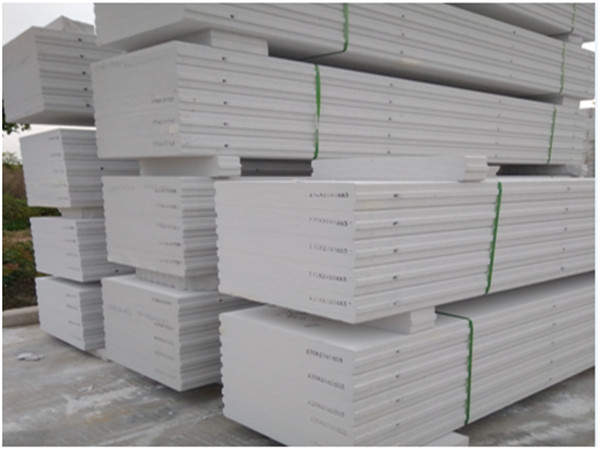

Now the country is vigorously promoting prefabricated buildings, and prefabricated buildings are ushering in good development opportunities. Autoclaved aerated concrete slabs are used as new wall materials because of their unique advantages. They are more and more popular, but what are the characteristics or advantages of aerated concrete slabs that are so popular with everyone?

1. What is autoclaved aerated concrete panel

Autoclaved aerated concrete panel is a new type of light-weight porous green environmental protection building material that uses cement, lime, silica sand and other main raw materials, and then adds different amounts of anti-corrosion reinforced steel mesh according to structural requirements. After high-temperature and high-pressure, steam curing, the reaction produces autoclaved aerated concrete slabs with porous crystals, which have a lower density than ordinary cement materials, and have excellent fire resistance, fire prevention, sound insulation, heat insulation, thermal insulation and other unparalleled performance.

2. Features and advantages of autoclaved aerated concrete panel

1. Lightweight: The specific gravity is only 500 ~ 650kg / m3, which is only 1/4 of the concrete and 1/3 of the clay brick. It is known as the concrete floating on the water. The design value is 650kg / m3.

2. Fire resistance: 100mm thick sheet can reach 3.82 hours, 125mm thick can reach more than 4 hours, it is a first-class fireproof material.

3. Thermal insulation: The thermal conductivity is 0.114, and the thermal insulation effect of its 125mm thick material can reach the ordinary 370mm thick brick wall. It is a new type of building material that can achieve more than 65% of building energy saving with a single material.

4. Sound insulation: the sound insulation index of 100mm thick plate (double-sided putty) reaches 40.8dB (transmission loss); the sound insulation index of 120mm thick plate (double-sided putty) reaches 45dB (transmission loss); 150mm thick plate (double-sided) (Putty) sound insulation index of 48dB (transmission loss); there are many small pores inside the AAC sheet, which has the dual performance of sound insulation and sound absorption.

5. Earthquake resistance: it can adapt to the larger interlayer angle displacement, allowing the interlayer displacement angle of 1/150, when using special contacts to reach 1/120, and in all cases of the interlayer displacement angle of 1/20 The board will not fall off at any time.

6. Environmental protection: no radiation, the hourly exposure is 12γμ / h, which is equivalent to the level on the outdoor grass; ALC is a new type of environmentally friendly building material, which can also save energy consumption during use. Building materials.

7. Carrying capacity: The inside of the board is equipped with double-layer, two-way reinforced mesh, providing external wall panels, partition wall panels, roof panels, floor panels, decorative panels, etc.

8. Crack resistance: ALC board is reinforced by anti-corrosion reinforced steel, and is cured by high temperature, high pressure and steam. It has the smallest shrinkage ratio among inorganic materials. It is caulked with special polymer binder to effectively prevent cracking.

9. Convenience: ALC board is processed by length measurement after actual measurement on site. It is a prefabricated product for the factory. It has high precision and can be planed, sawed and drilled. Dry operation is adopted, installation is simple, and the process is simple. The construction columns, waist beams, and plastering of the traditional wall are eliminated, and the putty is directly scraped, which greatly shortens the construction period, improves efficiency and construction quality.

10. Economical efficiency: ALC is used as the wall material, which can effectively increase the use area of the building, reduce the energy consumption, and reach the national building energy saving standard. Under the same sound insulation and fire protection requirements, the thickness of the ALC board is the smallest, and no structural columns Auxiliary components such as ring beams and waist beams can reduce the wall load and reduce the construction cost.

11. Creativity: ALC board can be made into artistic pattern plate. After the material is installed, the effect of brick pattern, grid pattern, horizontal pattern, brick imitation, stone imitation, etc. can be achieved directly.

12. Extensiveness: It can be used for fire protection and maintenance of concrete structure, steel structure house, frame structure, frame and shear structure office building, interior and exterior wall of factory building, floor slab, roof slab, firewall, explosion-proof wall, steel structure beam and column, Soundproof walls, retrofitting of old buildings, etc.

13. Diversity: Another 50mm sheet and 30mm ultra-thin board (can be used as external wall insulation board and fireproof board).

14. Fastness: Eliminate the mixing, masonry, plastering, steel bar, formwork, concrete and other types of work in the traditional block process. Only the panel installer can do all the work, avoiding the conflicts and mutual restrictions of the types of work.

15. Uniqueness: The width of AAC sheet is 600mm, the maximum length can be 6 meters (150mm thick), and the length of other sheets cannot reach 6 meters.

3. Application range of autoclaved aerated concrete panel

1. Old building renovation project. The energy-saving renovation of existing buildings is a cause that the country has planned to implement and will continue for a long time. In such projects, it is a wise choice to use lightweight exterior wall panels. Compared with other external wall materials, light-weight insulation wall panels are simple and quick to install, with short construction period and low cost. The construction has less interference with the normal work and life of the residents, and has the advantages of waterproofing and anti-aging. People’s welcome.

2. Inner and outer partition walls of office buildings, hospitals, school classrooms, office buildings, shopping malls, supermarkets, hotels and guest rooms, and the filling walls of residential and apartment civil buildings (including toilets, kitchens, household walls, partition walls and external walls) Wall, etc.). The common feature of this type of building is that there are many compartments, the internal structure is relatively simple and uniform, and the internal structure often needs to be adjusted according to customer needs, so it is more suitable to use lightweight partition boards.

3. Interior decoration. At present, the material used as the room partition is mainly light steel keel gypsum board. Compared with light wallboard, this material has low strength, poor sound insulation, poor durability, and no obvious advantage in price. Therefore, many users are now switching to light-weight wall panels as room partitions.

4. Because of the lightness of this material, this material is the most important wall building material workshop specially used in supporting steel structures (plants / public buildings / residentials, etc.) that have been developed abroad.

More recommendations about the characteristics of autoclaved aerated concrete panels:

Construction technology of autoclaved aerated concrete block