What are the advantages of AAC panel engineering application?

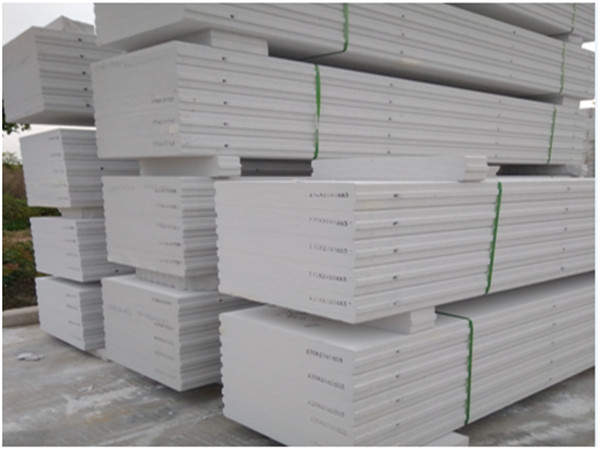

AAC panel is a new type of construction building material, which is widely used for its light weight, thermal insulation, fire resistance, sound insulation and other advantages. So, in the actual construction process, what are the specific advantages of AAC panel engineering application? Here is a brief introduction for everyone.

1. Reduce wet work on the construction site and increase construction efficiency

The use of blocks requires additional structural columns and seismic waist beams, and the construction of a single wall requires more than three days to complete. And the block wall needs to be plastered on both sides to meet the flatness requirements, and the wall plastering is completed, it takes more than 30 days to dry, and the coating and painting process can be constructed after drying. Lightweight aerated concrete wall panels are measured on-site and processed to a fixed length. The construction of a single-sided wall can be completed within 24 hours. The wall panel is dry construction, and there is no on-site wet operation. The flatness error of the wall after installation is not more than 3mm, the wall does not need to be plastered, and the construction process of wall paint can be entered after the construction is completed.

2. Save project cost

(1) Compared with 200mm thick aerated concrete block walls, AAC panels eliminate the need for structural columns and waist beams in the block walls to reduce the amount of steel and concrete; the walls do not need to be plastered with nets, but are scraped directly. Compared with the block partition wall, the project cost can be reduced by 15-25 yuan per square meter.

(2) Compared with aerated concrete block walls, AAC panels do not need to be equipped with structural columns and concrete waist beams, and the cubic dry bulk density of lightweight wall panels does not exceed 650kg (conservative design value is 850 kg per cubic meter); aerated concrete blocks There are masonry mortar, concrete waist beams, structural columns and plastering mortar on both sides (concrete bulk density is 2400 kg per cubic meter, cement mortar bulk density is 2000 kg per cubic meter). Under normal conditions, the combined cubic bulk density is about 1300 -1400kg. The use of this lightweight panel can better reduce the load-bearing load of the structure; at the design stage, the steel content can be saved by about 4-6kg per square meter (that is, about 20-30 yuan per square meter) according to the calculation of the plate weight and the structural load;

(3) It can be seen from the above two items that because the overall load of the wall is greatly reduced, the structural beams and foundations of the project can also be reduced in cross-section size and concrete markings, and even the buried depth and excavation depth of the foundation can be reduced. The square meter is reduced again by about 15-25 yuan;

(4) Wall reform fund: aerated concrete block walls, wall reform funds generally return 70-80%; with AAC panels, wall reform funds are charged at 10 yuan per square meter of building area, and wall panels can save 2-3 per square meter. Yuan cost.

AAC panels can increase construction efficiency, shorten the construction period, and more importantly, save about 80 yuan per square meter of project cost. So the practical application value is very high. The above is the advantages of AAC panel engineering application, I hope to help you have a more detailed understanding of AAC panels.

For more information about the advantages of AAC panels, please click to visit:

What are the performance of AAC panel?

Features and Advantages of Autoclaved Aerated Concrete Products

What are the advantages of autoclaved aerated concrete panels?