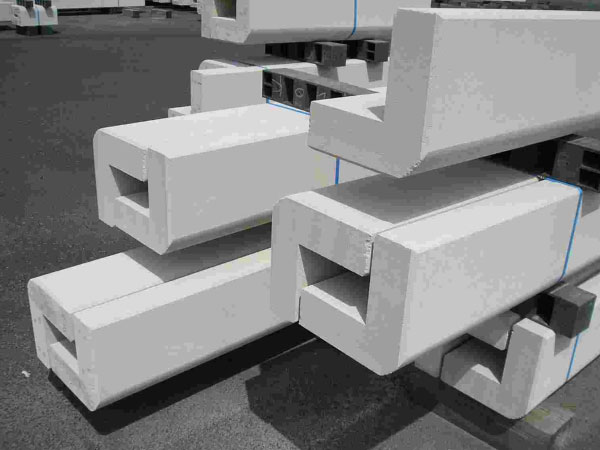

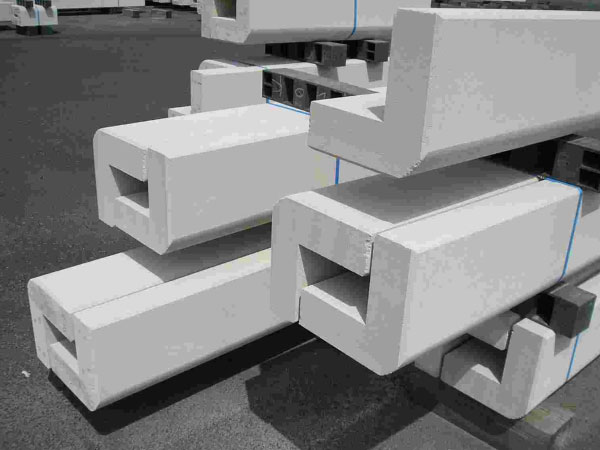

Autoclaved aerated concrete block has light weight, thermal insulation performance, good fire resistance performance, good energy saving and environmental protection, effective use of industrial waste, economical cost, and more importantly, it has strong shape and convenient construction by workers. It is precisely because of these advantages that aerated concrete blocks are widely used as infill walls.

There are two masonry methods for autoclaved aerated concrete blocks: one is to bond the mortar to build the mortar joint with a thickness of 3.4mm. The second method is cement mortar, cement mixed mortar or autoclaved aerated concrete block masonry mortar masonry. At present, most construction sites use the second method. So what are the construction standards for autoclaved aerated concrete blocks, let’s take a look at them in detail!

(1) The masonry of autoclaved aerated concrete blocks must strictly comply with the technical index requirements of the national standard “Code for Construction Quality Acceptance of Masonry Engineering” (GB 50203-2002).

(2) Reasonably arrange the construction period and do not blindly rush to work. If possible, try to avoid building during the rainy season.

(3) Masonry mortar should use special mortar with good bonding performance, its strength grade should not be less than M5, the mortar should have good water retention, and inorganic or organic plasticizers can be mixed into the mortar. If possible, special aerated concrete masonry mortar or dry mortar should be used.

(4) In order to eliminate the shrinkage cracks between the main structure and the enclosure wall due to temperature changes, tie bars must be left at the junction of the block and the wall column, and the vertical spacing is 500-600mm (according to the selected product (Determined by the height specification), press-buried 2Ф6 steel bars, with both ends extending into the wall not less than 800mm; in addition, when the masonry is 1.5m high, 2Ф6 full-length steel bars should be used to prevent shrinkage and cracking of the wall.

(5) Set up structural beams and columns in walls with larger spans or heights. Generally, when the wall length exceeds 5m, a reinforced concrete structural column can be installed in the middle; when the wall height exceeds 3m (≤120 thick wall) or 4m (≥180 thick wall), a reinforced concrete waist beam can be added at the waist of the wall.

(6) The junction of the window sill and the wall between the windows is the place where the stress is concentrated, and it is easy to cause cracks due to the shrinkage of the masonry. Therefore, it is advisable to install reinforced concrete cast-in-place tape at the window sill to resist deformation. The upper corners of the door and window openings are also prone to cracks and hollows, and ring beams should be used here instead of lintels.

(7) The horizontal unevenness of the aerated concrete exterior wall (such as molding, rain cover, eaves, window sill, etc.) should be flooded and dripped to avoid water accumulation.

(8) Calculate the number of skins and rows according to the block size before masonry, check and correct the tie bars. A certain height of plain concrete with the same thickness as the wall can be pre-poured at the root of the wall. At present, the commonly used method is to lay two red bricks, leaving a gap of about 20mm high on the top skin, so as to use the same material as the original block. The solid auxiliary small blocks are laid obliquely and squeezed tightly.

(9) Since the performance indexes of aerated concrete blocks of different dry density and strength grades are different, the aerated concrete blocks of different dry density and strength grades should not be mixed, and the aerated concrete blocks should not be mixed with other bricks. , Block mixing.

(10) Strictly control the moisture content of the aerated concrete block on the wall. According to relevant regulations, the moisture content of aerated concrete blocks should be less than 15% during construction, and less than 20% for fly ash aerated concrete products. The drying shrinkage law of aerated concrete shows that the shrinkage value of the moisture content between 10-30% is relatively small (usually 0.02-0.1mm/m).

According to experience, it is appropriate to control the moisture content of aerated concrete blocks at 10-15% during construction. The moisture depth of the blocks should be 8-10mm on the surface. The moisture depth of the surface can be observed by scraping or knocking on a small side. Determined by experience. Under normal circumstances, watering 24h before masonry, the amount of water should be determined according to the season and dry and wet temperature at the time of construction, controlled by the surface wetness. It is forbidden to directly use blocks full of rain or excessive watering.

(11) The daily height of aerated block masonry shall be controlled within 1.4m, and the daily height of aerated block masonry shall be controlled within 1.2m during spring construction, and the masonry shall be stopped on rainy days. When the masonry reaches about 200mm from the bottom of the beam, it should be statically stopped for 7 days after the masonry is deformed and stabilized, and then the solid auxiliary small blocks of the same material are used to squeeze the solid auxiliary block.

(12) When building aerated blocks, the mortar joints should be horizontal and vertical, and the upper and lower layers should be cross-staggered. The corners should bite each other. The mortar should be full. The horizontal mortar joints should not exceed 15mm and the vertical mortar joints should not exceed 20mm. The fullness is required to be above 90%, and the vertical joints should be grouted with internal and external temporary splints. After the masonry, the internal and external mortar should be used to hook the joints to ensure the fullness of the mortar.

(13) The construction joints of the wall must be built into sloping chaps, and the length of the sloping chaps should not be less than 2/3 of the height.

(14) After the wall is built, rain-proof cover should be done to avoid direct rain showering on the wall; the wall of the outer wall facing the sun should also be shaded to avoid the high temperature causing the moisture in the mortar to volatilize too fast, if necessary Spray water with a sprayer for maintenance.

(15) At the junction of the block wall and the concrete beams, columns, and shear walls, as well as the frame of door and window holes and the inner corners, nail and hang a 10mm×10mm mesh size steel mesh, each side is 200mm wide, and the mesh should be overlapped. It is flat and firmly connected, and the lap length is not less than 100mm.

(16) When chiseling grooves and laying pipes on the wall, special tools should be used instead of an axe or tile knife. The surface of the pipe should be 4~5mm lower than the wall surface, and the pipe and the wall should be clamped firmly. Loose, rebound, and then water and moisten, the filling strength is equal to the mortar used for masonry, and the wall is leveled, and 10mm×10mm steel wire mesh should be laid along the pipeline laying direction, and its width should span the slot, and each side should not be less than 50mm, tightly nailed.

The above is all the introduction to the construction standards of autoclaved aerated concrete blocks. With the continuous advancement of wall material innovation, autoclaved aerated concrete blocks are used as a new type of building wall material with light weight, sound insulation and good thermal insulation properties. It has gradually been widely used in construction projects, and the application of autoclaved aerated concrete blocks has a good development prospect.